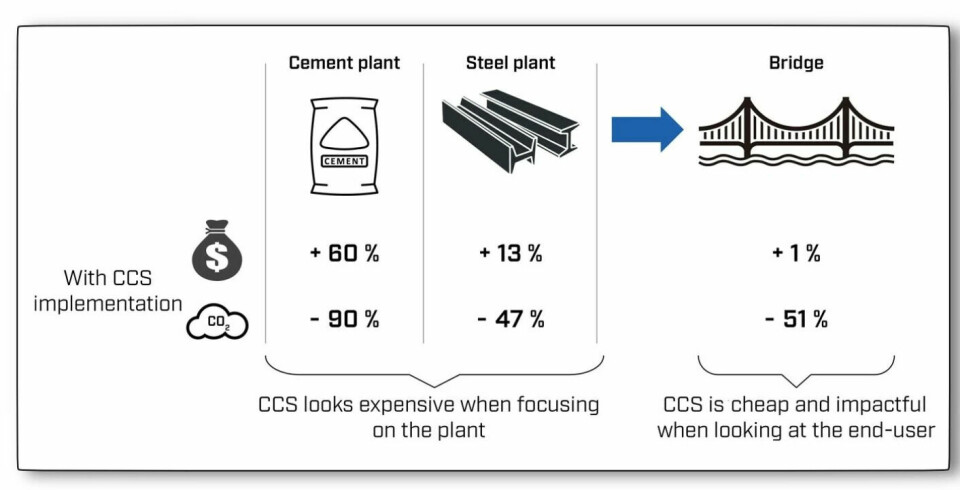

It's remarkably cheap to capture CO2 in large construction projects

A new study shows that the construction of a large bridge only needs to be one per cent more expensive to ensure half of the greenhouse gas emissions are reduced.

The research by scientists at SINTEF is now gaining international attention.

Carbon capture and storage, abbreviated as CCS, has often been criticised for being too expensive, especially when applied in the context of construction projects.

“Many studies have examined the economic impact of CCS on raw materials such as cement and steel. However, they haven't looked at the price of the final product,” researcher Simon Roussanaly told Geoforskning.no (link in Norwegian).

Only 1 per cent more expensive

In this new Norwegian study, the researchers investigated the construction of the world's longest bridge over water.

It is no coincidence that they chose the famous Lake Pontchartrain Causeway in Louisiana, USA, as the calculation example. It is 38 kilometres long and crosses a large lake north of New Orleans. The bridge is made of approximately 75,000 tonnes of cement and nearly 25,000 tonnes of steel.

The SINTEF study shows that if CO2 capture and storage had been used in this bridge project, it would initially lead to a significant increase in the costs of the individual raw materials.

The price of cement would have increased by as much as 60 per cent, and the steel price would have increased by 13 per cent.

At first glance, this may seem like a frighteningly high price increase.

Cement and steel account for 15 per cent of greenhouse gas emissions

However, the researchers believe that it is important to put these costs into perspective.

Surprisingly, cement and steel account for only a small portion of the total costs of a construction like this, despite the large consumption of cement and steel.

Therefore, the overall cost increase for the project would be no more than about one per cent if CCS is implemented.

The study from SINTEF is so remarkably significant that it is mentioned in the research journal Science.

“To achieve our climate goals, we are dependent on CCS. It is good news that it is an effective climate technology and not particularly costly in our study. Therefore, it is great that this research is now gaining international visibility,” Roussanaly told Geoforskning.no.

The cement and steel industries alone account for a total of 15 per cent of global CO2 emissions. If we can reduce these emissions, it could have a significant impact on global warming.

———

Translated by Alette Bjordal Gjellesvik.

Read the Norwegian version of this article on forskning.no

Reference:

Subraveti et al. Is Carbon Capture and Storage (CCS) Really So Expensive? An Analysis of Cascading Costs and CO2 Emissions Reduction of Industrial CCS Implementation on the Construction of a Bridge, Environmental Science & Technology, vol. 57, 2023. DOI: 10.1021/acs.est.2c05724